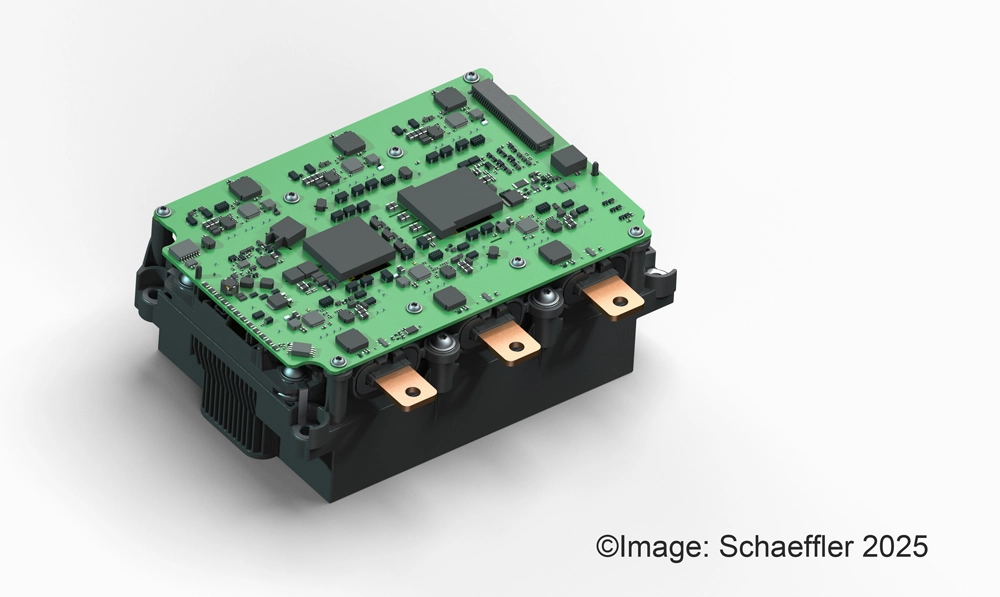

High voltage inverter brick

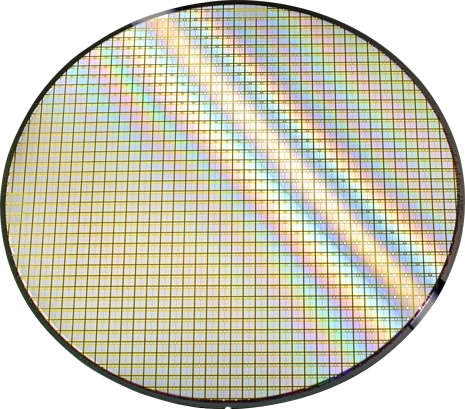

SiC MOS Wafer

ROHM and Schaeffler, a leading German automotive supplier, have started mass production of a new high-voltage inverter brick equipped with ROHM’s SiC (silicon carbide) MOSFET bare chips as part of their strategic partnership. The inverter brick is intended for a major Chinese car manufacturer.

The Schaeffler inverter subassembly is the essential power device building block (brick) to control the electric drive via logic signals. This is where the high-frequency current pulses are produced that set the vehicle’s electric motor in motion. The performance characteristics of the inverter brick now being produced are impressive: Schaeffler increased the output of the brick by increasing the maximum possible battery voltage to much more than the usual 800 V – and with RMS currents of up to 650 A, which turn the sub-module into a compact power pack.

“Through our strategic approach of incorporating scalability and modularity into our e-mobility solutions – from individual components to a highly integrated electric axle – we developed the readily integrated inverter brick. Based on our generic platform development, it took us just one year to bring this optimal product for the popular X-in-1 architectures to volume production readiness,” says Thomas Stierle, CEO of the E-Mobility Division at Schaeffler.